Our Story

Our Mission

Our mission is to become the most trusted enterprise in the semiconductor industry for consumable parts. We are committed to delivering unparalleled quality, reliability, and innovation in every product we offer, ensuring that our clients can depend on us to meet their evolving needs.

Our Vision

Continually innovate to meet our customers' needs while also creating meaningful value for our colleagues. We believe that by understanding and anticipating the challenges faced by our clients, we can develop solutions that not only drive their success but also foster a collaborative and supportive environment for our team.

Core Values

Honesty

Since our founding, we have adhered to a principle of integrity in our operations, dedicating ourselves to serving each client with care and aiming to build long-lasting customer relationships. This commitment extends not only to our interactions with clients but also to the collaboration among our employees and our dedication to social responsibility.

Innovation

We encourage our employees to break with traditions and propose innovative solutions for product development, service enhancement, and process optimization. This core value helps us address ever-changing challenges and ensures we remain at the forefront of the industry.

Teamwork

Our team members have always been the key to the smooth operation of the company. Through collaboration and support, we continue to advance in a competitive market, achieve longterm goals, and create a brighter future.

Confidence

We have great confidence in our products, believing they can meet and exceed customer expectations. However, we remain humble and continue to strive for excellence, seeking improvements and innovations in order to provide our clients with superior products and services.

Milestones

Our advantages

Rich Industry Experience

MPP possesses over 25 years of extensive experience in the semiconductor front-end process, specializing in thin film, diffusion and etching processes. We have established long-term partnerships with several leading wafer foundries, with our major clients including:

- TSMC:F3, F5, F6, F7, F8, F12, F14, F15, F18, F16 (Nanjing), F21 (Arizona), F23 (Kumamoto), AP5A (Assembly and test factory

- UMC: F8A, F8B, F8C, 12A, 12I, USCXM (Xiameng)

- Leading wafer factories in Singapore

- VIS, MICRON, PSMC, PDMC, Nanotech, SCREEN…

Our expertise enables us to deliver high-quality products and services that meet stringent requirements and help our clients maintain a leading edge in a competitive market.

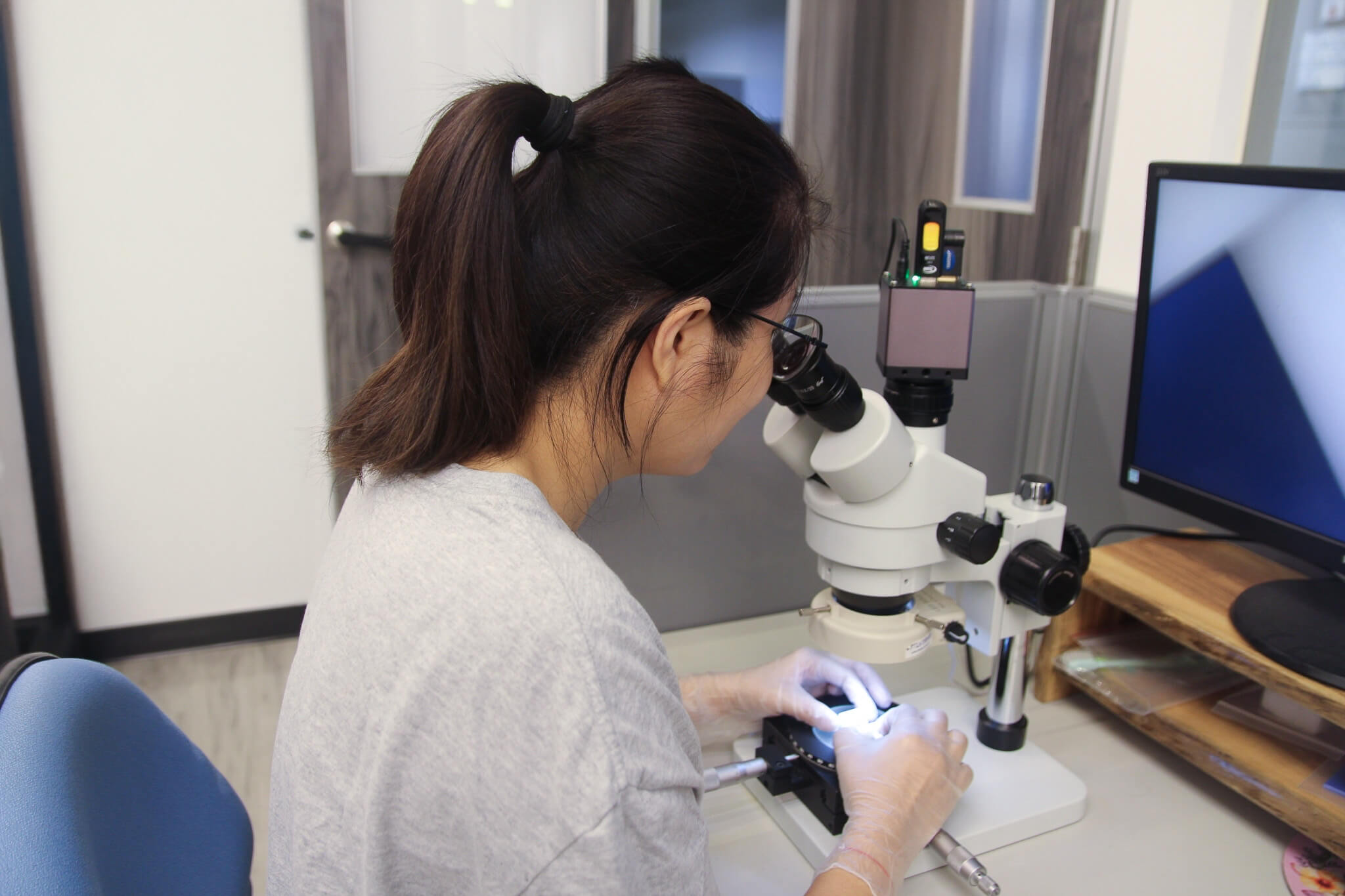

High quality products

Under the cleanroom environment and the strict monitoring of inspection instruments, we ensure that every component meets the highest quality standards to satisfy the needs of our semiconductor industry clients. Our quality control and inspection equipment includes¡

Our quality control and inspection equipment includes:

- Clean Room Class 100/100:

- Handheld X-Ray Fluorescence (HHXRF) analyzer

- 3D Measuring Machine

- Flow Meter

- Microscope

- Digital Caliper

- Ultrasonic cleaning treatment

- Vacuum packing machine

- Granite platform (DIN 876/Grade 00)

- Height measuring instrument

- Ultra-pure water cleaning system

- KEYENCE LM-X Multisensor Measurement System

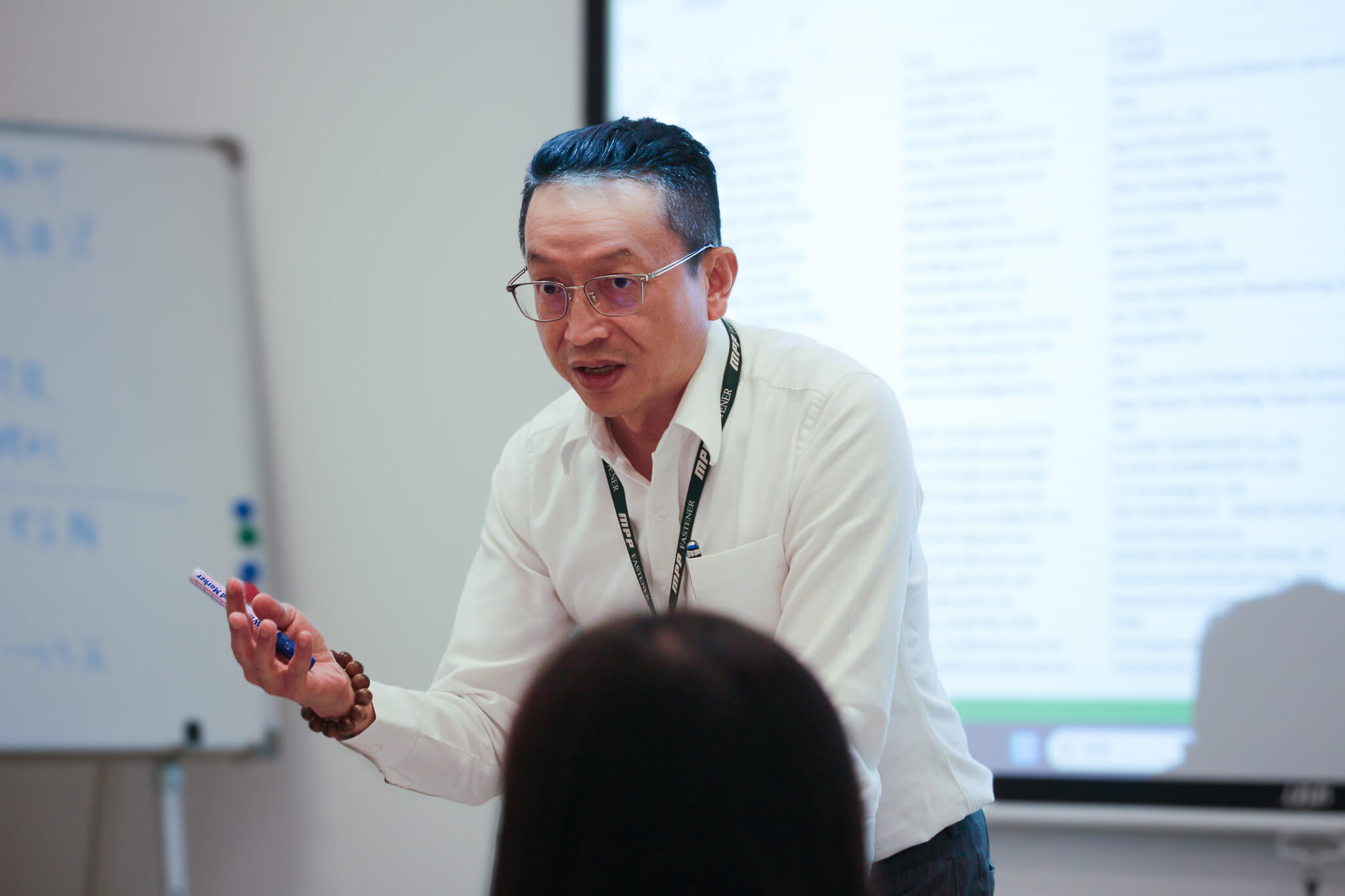

Professional team

Our engineers are dedicated to understanding clients' needs and applying their professional expertise to help design solutions that best suit clients operational environments.

Guaranteed International Standards

We are well-versed in the demands of the semiconductor industry and strictly adhere to international standards and regulations to ensure our products comply with market requirements worldwide.

Prompt Response

We are committed to providing our clients with fast and efficient service. Whether it's consolidating issues or implementing solutions, we can offer professional advice and take action shortly.