CIP (Continuous Improvement Process)

Our engineering team has accumulated extensive professional experience and knowledge in Fabs, assisting in solving clients' preventive maintenance (PM) issues and designing jigs and fixtures based on customer needs. Through Continuous Improvement Process (CIP) solutions, we aim to enhance clients’ overall production efficiency and to help clients reduce downtime risks, save labor costs, and increase the efficiency of PM processes.

User cases

Handheld Fork

Problem: When the machine malfunctions, the robot can’t operate normally

Solution: Use a handheld fork to retrieve and transfer wafers

from the loadlock to foup for storage

Benefit: Prevents direct handling with bare hands, thus

avoiding contamination and preserving wafer cleanliness

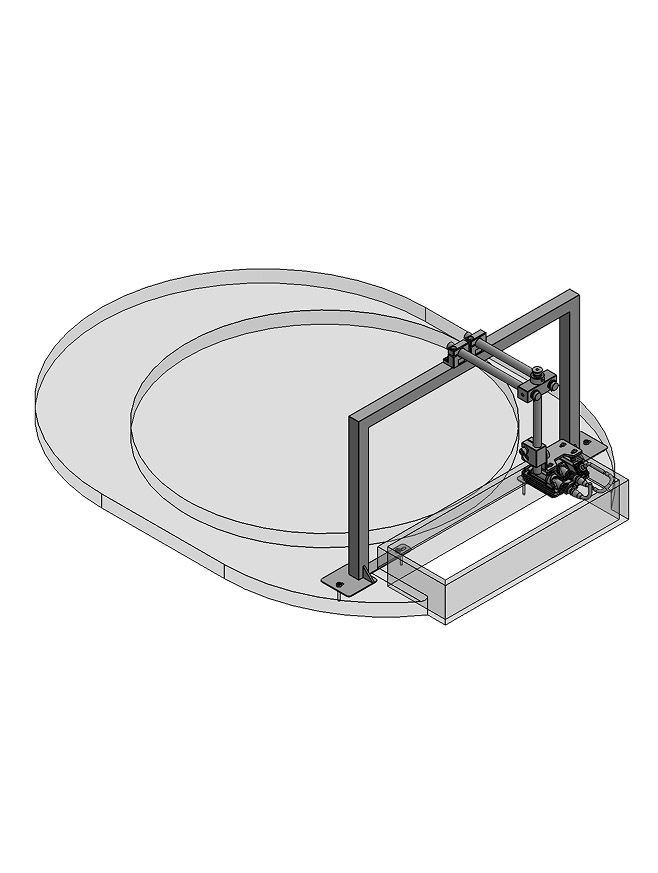

Contactless Loadlock Height Measuring Gauge

Benefit:

- Detects blade height to prevent wafer scratching during transfer

- Utilizes optical sensing to replace traditional contact-based distance measurement

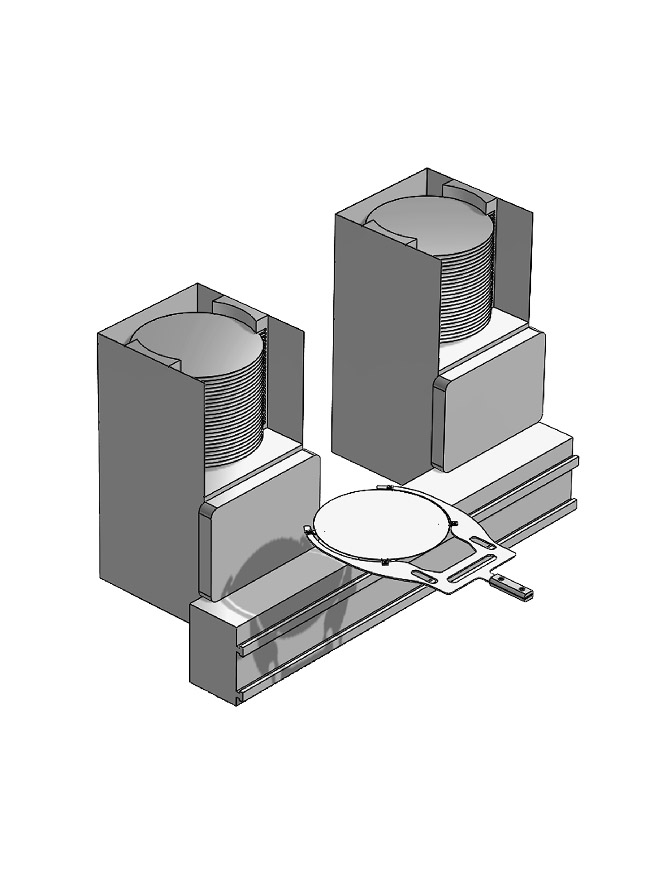

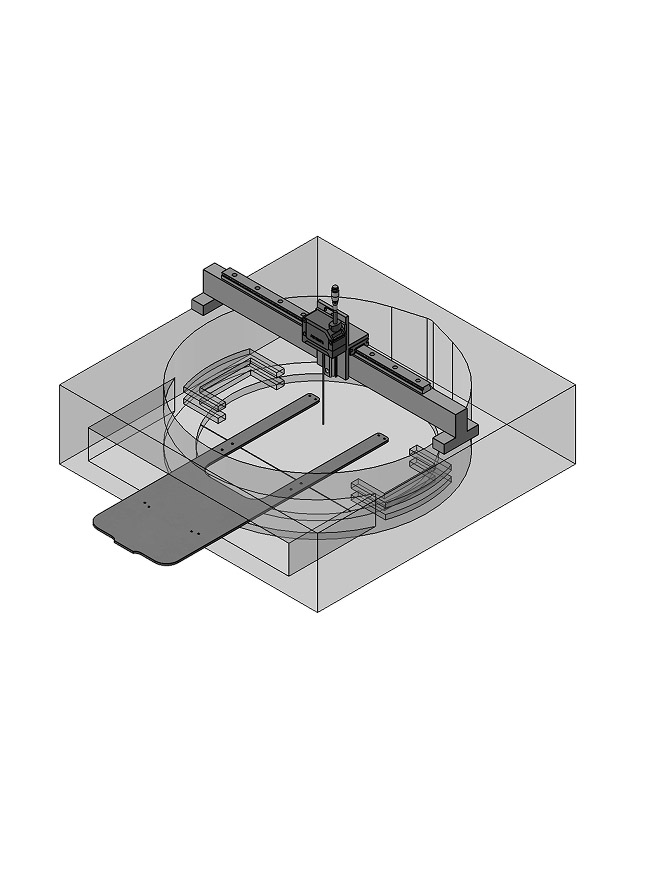

Sensor Positioning Device

Problem: Traditional robot alignment and positioning rely on

visual inspection

Solution: Use a sensor-calibrated fixed position as a

reference point to detect any deviation in the robot's

position

Benefit: The sensor can store detection data, enabling

quantitative analysis

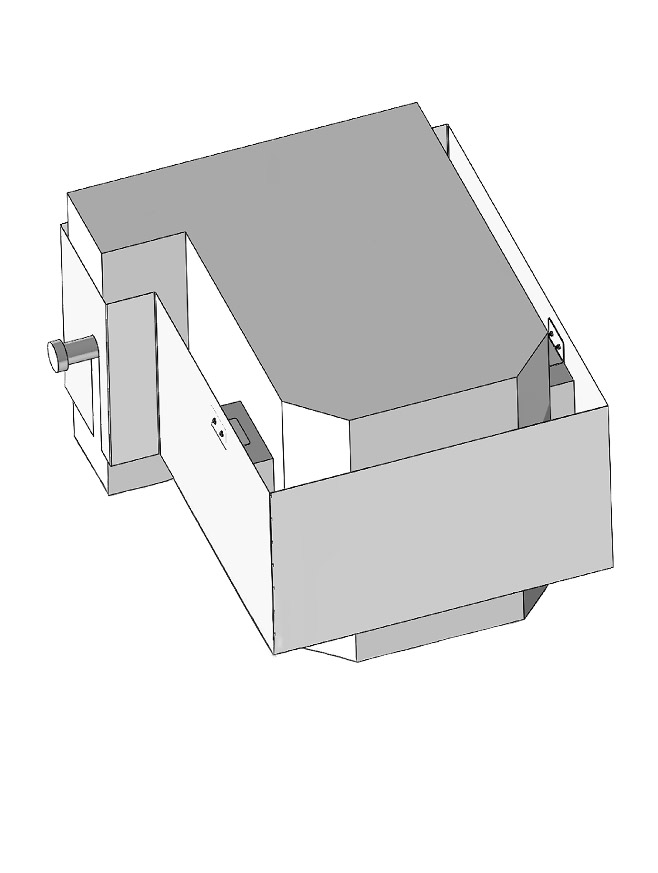

RF(Radio frequency) shielding

Problem: The receiver is susceptible to interference from

devices that emit electromagnetic waves, leading to incorrect

commands

Solution: Use permalloy for efficient magnetic field shielding

to isolate electromagnetic waves

Benefits: Significantly reduces electronic signal

interference

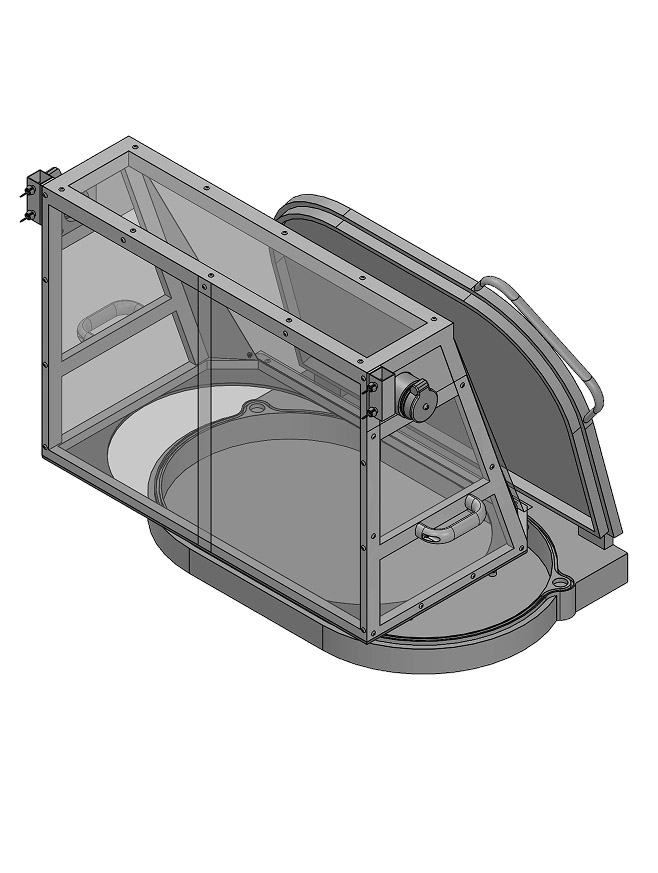

Hood Connected Curtain Accry

Problem: Prevent residual gases from escaping the chamber

during PM

Solution:

- Use a mask to reduce inhalation of residual gases by PM personnel

- Restrict gas leakage and simultaneously use a CV tube to extract remaining gases

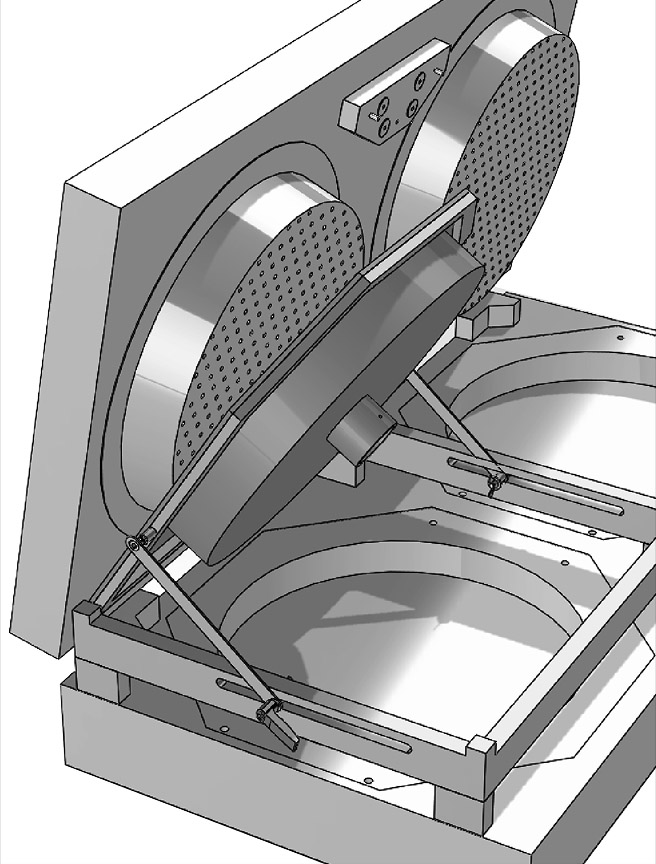

Shower Head Purge Gauge

Problem: How to improve the cleanliness of the shower head

Solution:

- Perform pump and vent cycles using nitrogen

- Blow out residual particles from the shower head nozzles to meet cleanliness requirements

Design the jigs and fixtures based on your need!

Reach out to us for more information and sharing your project details.

Contact us