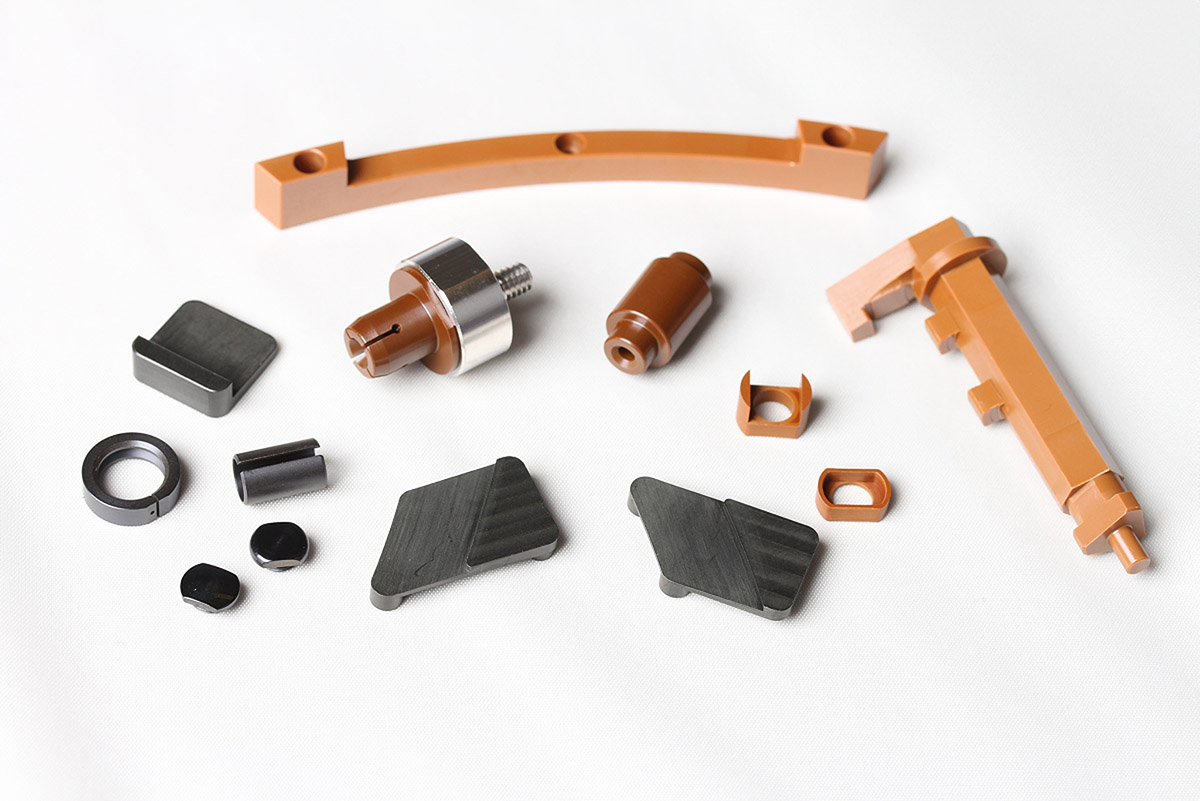

High Performance Plastic Parts

Materials

Dupont Vespel®

Celazole® U-60SD PBI

Contact

Material Details

Celazole® U-60SD PBI

Celazole® PBI (Polybenzimidazole) is the world’s highest performing thermoplastic - known for its superior high temperature and plasma resistance, high strength, dimensional stability and wear resistance. Celazole U-60SD is a semiconductor grade PBI thermoplastic recommended for use in Dry Etch Chambers and Sputtering Systems.

The material is ideally suited for:

- Oxide Etch Chamber Seal

- Oxide Etch Lifting Pin

- Interior Chamber Screws and Components

- Focus Rings

- Wafer Clamps

- Sputtering Chamber Seals

- Sputtering Chamber Clamps and Components

Property highlights:

- High purity

- Plasma Resistance to CF₄、F、O₂ and Ar plasma

- Heat resistance up to 800°F

- 57,000 psi Compressive Strength

- Low Outgassing

- CTE 2.3 E-5/C

- Superior Abrasion Resistance

Materials

PEEK®

PEEK®+Carbon fibers

PEEK®+Glass fibers

Contact

Material Details

PEEK®

PEEK® is a semicrystalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures.

PEEK®+Carbon fibers

PEEK®+Carbon fibers has been reinforced with carbon fibers that improve PEEK®’s compressive strength and stiffness, while also reducing its expansion rate. The grade of PEEK offers the best wear resistance and load bearing capabilities, while also offering 3.5 times higher thermal conductivity than unfilled PEEK®.

PEEK®+Glass fibers

PEEK®+Glass fibers has been reinforced with glass fibers, which significantly reduces its expansion rate. This makes it ideal for applications that require improved stability, strength, and stiffness at temperatures above 300℉.

Materials

PTFE+CF 25%

60% Bronze+PTFE

Torlon PAI-4301

Torlon

PAI-4203

Torlon PAI-5530

Contact

Material Details

PTFE+CF 25%

- Teflon with 25% carbon fiber added, excellent wear resistance and mechanical strength

- PTFE has the best chemical corrosion resistance and the lowest friction coefficient, allowing use at temperatures between 180 to 270 ℃ without load.

60% Bronze+PTFE

- Excellent compressive and wear resistance characteristics.

- Due to its metallic properties, it has better thermal conductivity.

Torlon PAI-4301

Adding PTFE Teflon and graphite

- Good wear resistance, low friction coefficient

- Used in applications with extremely high wear requirements, such as oil-free lubricated bearings, seals, and bearing isolators.

Torlon PAI-4203

Polyamide-imide

- It is one of the best in toughness and impact strength among TORLON PAI.

- Due to its inherent high-temperature resistance, dimensional stability, good machinability, it also has excellent electrical insulation.

Torlon PAI-5530

Polyamide-imide with 30% glass fiber added

- Reinforced with 30% glass fiber, providing better rigidity, higher strength, and good creep resistance

- Supports fixed loads for extended periods at high temperatures, demonstrating excellent dimensional stability at 250°C

Materials

Polytetrafluoroethylene (PTFE)

Silicone rubber

Polyethylene

terephthalate (PET/PETE/obsolete PETP)

PFA

PCTFE

Contact

Material Details

Polytetrafluoroethylene (PTFE)

Polytetrafluoroethylene (PTFE) a strong, tough, waxy and nonflammable synthetic resin. PTFE is distinguished by its slippery surface, high melting point and resistance to attack by almost all chemicals. Theses properties have made it familiar to consumers as the coating on nonstick cookware ; it is also fabricated into industrial products including bearings, pipe liners and parts for valves and pumps.

Silicone rubber

Silicone rubber is generally non-reactive, stable, and resistant to extreme environments and temperatures from -55℃ to +300℃ while still maintaining its useful properties. Due to this properties and its ease of manufacturing and shaping, silicone rubber can be found in a wide variety of products, including automotive applications, cooking, banking, food storage products and apparels.

Polyethylene terephthalate (PET/PETE/obsolete PETP)

Polyethylene terephthalate (PET/PETE/obsolete PETP) is the most common thermoplastic polymer resin of the polyester family and is used in fibre for clothing, containers for liquids and foods, thermoforming for manufacturing, and in combinaison with glass fibre for engineering resins.

PFA (Perfluoroalkoxy Alkane)

Known as Perfluoroalkoxy Alkane, is a high-performance fluoroplastic.

- Temperature Resistance: Capable of stable operation over a wide temperature range from -200°C to 260°C, with a high melting point of approximately 305°C.

- Corrosion Resistance: Resistant to all strong acids, strong bases, strong oxidizing agents, reducing agents, and most organic solvents. It is only slightly corroded by fluorides and high-concentration alkali metal solutions.

- Electrical Insulation: Exhibits extremely low dielectric loss and a high volume resistivity up to 10^18 ohm·cm, making it an ideal material for high-frequency applications.

- Self-Lubrication: Possesses a low coefficient of friction, suitable for applications requiring oil-free lubrication or reduced frictional loss.

PCTFE (Polychlorotrifluoroethylene)

Known as Polychlorotrifluoroethylene, is a high-performance fluoropolymer.

- Excellent Chemical Stability: PCTFE is inert to most chemicals and exhibits good corrosion resistance, second only to PTFE (Polytetrafluoroethylene).

- Outstanding Low-Temperature Performance: PCTFE maintains excellent mechanical properties even in extremely low-temperature environments, such as those involving liquid nitrogen or liquid oxygen. It is therefore widely used in cryogenic equipment and storage/transport systems.

- Good Gas Barrier Properties: PCTFE has an extremely low gas permeability rate among the lowest of all transparent plastics, making it an excellent gas barrier material.

- High Hardness and Strength: PCTFE features outstanding mechanical strength and hardness, along with good dimensional stability.

Similar products